|

HOME |  |

ABOUT US |  |

|

SERVICES |  |

CONTACT US |  |

|

||||||||||||

|

||||||||||||

|

||||||||||||

|

Aluminium : Dura-Clad

Dura-Clad: Cladding Sheets:

Dura-Clad® panel is made from Aluminium Alloy AA3003 H24 temper, which is widely used, in marine and industrial applications. Its is superior in flatness and non-combustible DIN Standard. Dura-Clad® is manufactured from state of art coil-coating system using PVF2/PVDF (Kynar 500/ Hylar 5000 resin) paint. It comes in 2 coats for solid colour or 3 coats for metallic finish. Dura-Clad® is highly consistent in colour stability , gloss retention, resistance to UV-A, UV-B & UV-C radiation and remains very beautiful for a very long time. Material Specifications:

The compositions of Dura-Clad® panels are as below :

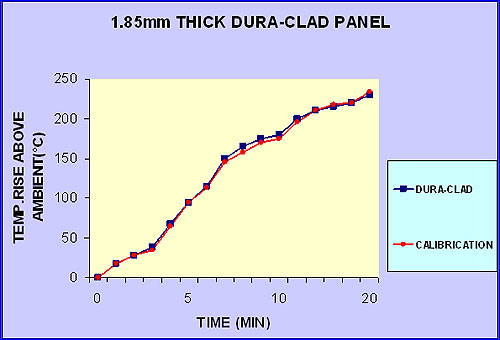

Standards For Fire Requirement Dura-Clad® with PVF2/PVDF Fluorocarbon coatings have been tested and approved by SIRIM for :-

Dura-Clad® Panels COMPLY with the Fire Requirements for Materials specified Under the Malaysia Uniform Building By-Laws (UBBL) 1984. * Index I indicates fire propagation index is 0.8 * Class One indicates surface of surface spread of Flame.  Coil Coating Process Coating on a high speed technologically advanced paint-line. Surface pre-treatment by Chromating, cover layers, primer and stoving of paint at temperatures between 249°C to 254°C. Wet film thickness 59-67 microns ensures excellent durability and excellent Surface finishes for exterior applications. Paint Coating Specifications

PAINT FORMULATED FROM KYNAR 500 / HYLAR 5000 PVDF Formulated to contain minimum amount of 70% Polyvinylidene Fluoride polymer which leads to excellent product performance for external application via high speed paint line for colour consistency of Pre-painted coils. Resin system – Fluorocarbon / acrylin Solvent system – Ester / Ketones.

|

Product

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copyright 2011. All right reserved. |

|